Tabla de Contenidos

Multinational dedicated to coffee based in Switzerland trusts Prodec

Prodec’s integration of doypacks packaging was carried out at a multinational company dedicated to coffee, children’s nutrition and chocolates with headquarters in Switzerland trust in PRODEC since 1983. They have also offices and factories around the globe and has been awarded the largest food company in the world for several consecutive years. This first equipment for the cereal sector travelled to its plant located in Spain as the first of more than 100 units currently installed in its different plants all over the world

The fascinating coffee route: A journey from the plant to the supermarket

Our corporate ethics and values revolve around the well-being of individuals and families. That is why we have always been proud to work for large accounts that share this vision and mission with us, like the one we show today in this video.

Coffee is not only an aromatic drink, but a global economic engine and its production and consumption impact the entire world. Prodec is proud to contribute to the value chain of this industry with a long journey in its process, which begins from cultivation in the plantations, harvesting, processing, roasting, grinding, primary packaging until the end with the secondary packaging, when Prodec is in action, before the final distribution.

We have been developing our own technology for many years, which led us to specialize in the cartoning and case packaging of flexible packaging, to later position ourselves as experts in flexible packaging. A long journey in flexible packaging but also many projects for the coffee industry, allow us to always offer the best solution for case packaging coffee bags or cases.

The optimal solution for high-speed automatic case packing of coffee bags

One of the greatest complexities that we face in automating lines of this type is the handling of the product, since all flexible packaging, such as pillow bags, doypacks, pouches, sachets and all their varieties, are highly unstable and there lies precisely one of our greatest achievements and expertise.

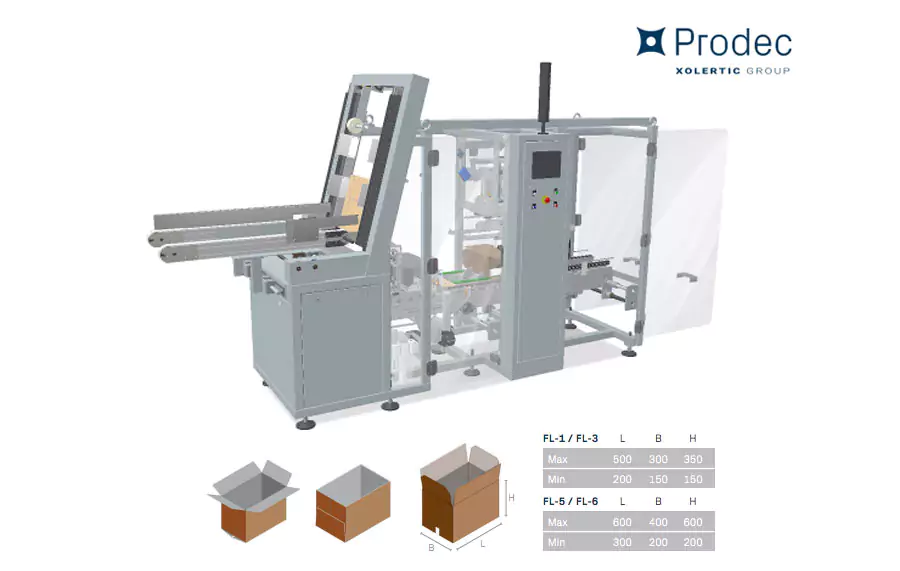

Our FL series side loading case packers are designed to highly efficiently case pack semi-rigid, unstable or deformable products with a grouping system we call BC, which works by moving the grouping of product downward. This type of application for the coffee industry, like the one we show in the video, are automatic high-speed case packing systems that guarantee maximum efficiency, safety and profitability of the equipment.

Do you want to know more about FL side loading nesting solutions?

Download Prodec FL-1 catalogue

Operation Inserting side-loading doypacks FL-1 Prodec

The bags arrive lying down via an infeed conveyor system made up of two bucket sections. Then, the grouping of the packages by means of a mechanically operated descender forms the floors step by step, until the number of floors preset in the program is achieved. Once the grouping is done, a lateral pusher moves it to a transfer platform, which places it in front of the preformed case for its introduction into it.

Other related products:

Request a quote

We design solutions that increase the productivity of your company and improve the quality of life of your employees. Request your quote in just 1 minute!

Request a quote