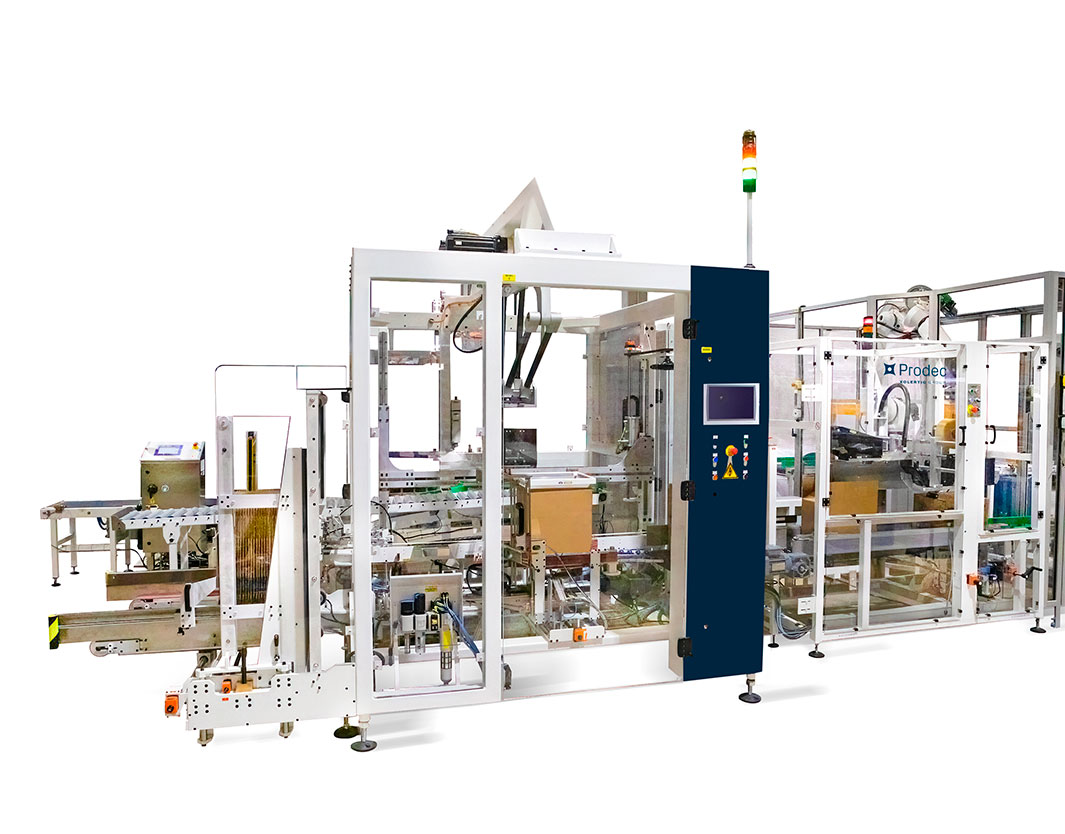

K-200 Top loading socket

K-200 Top loading socket

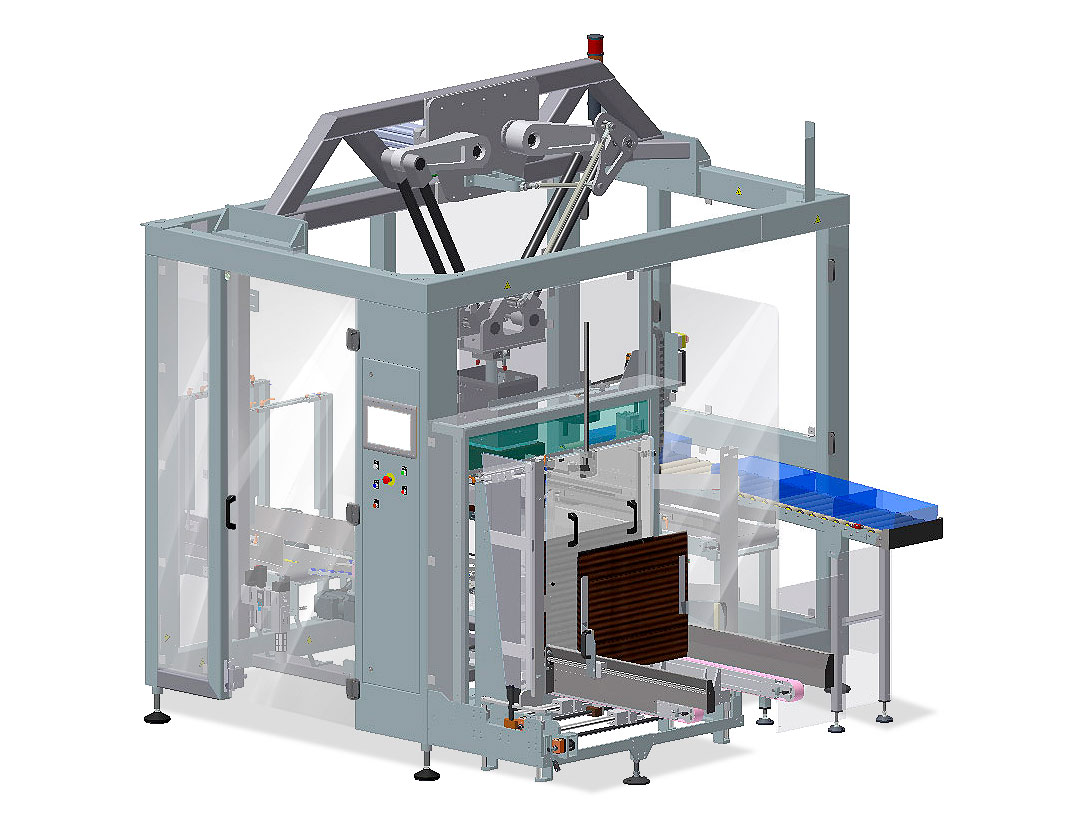

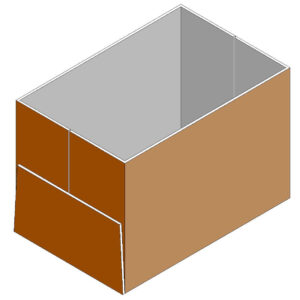

New case packing solution using a servo-controlled two-axis mechanism, with higher speed and performance compared to the Cartesian system. It is driven by two arms, each with two carbon fiber tubes, which provides high tensile and compressive strength, as well as weight reduction. Boxes are formed and products are packed in the same unit.

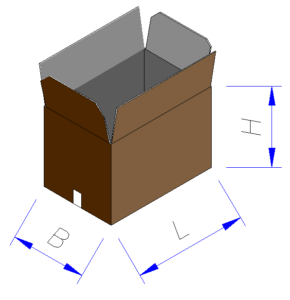

Box dimensions

| L | B | H | |

| Max | 500 | 300 | 420 |

| Min | 300 | 200 | 150 |

Benefits

- Solution for spaces of limited height

- Great savings in maintenance costs and time

- Versatile machine for adaptation to different formats

- Ergonomic design

- Quick format changeover

Features

- Production:

Maximum 10 cycles/min (heavy products)

Maximum 30 cycles/min (light products) - Single, double or triple head, with or without rotation and with 2 or 3 quintuple suction pads

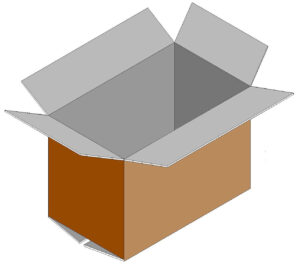

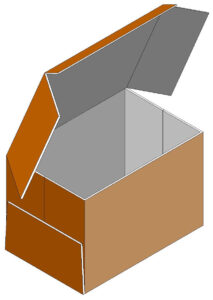

- Integrated case erector

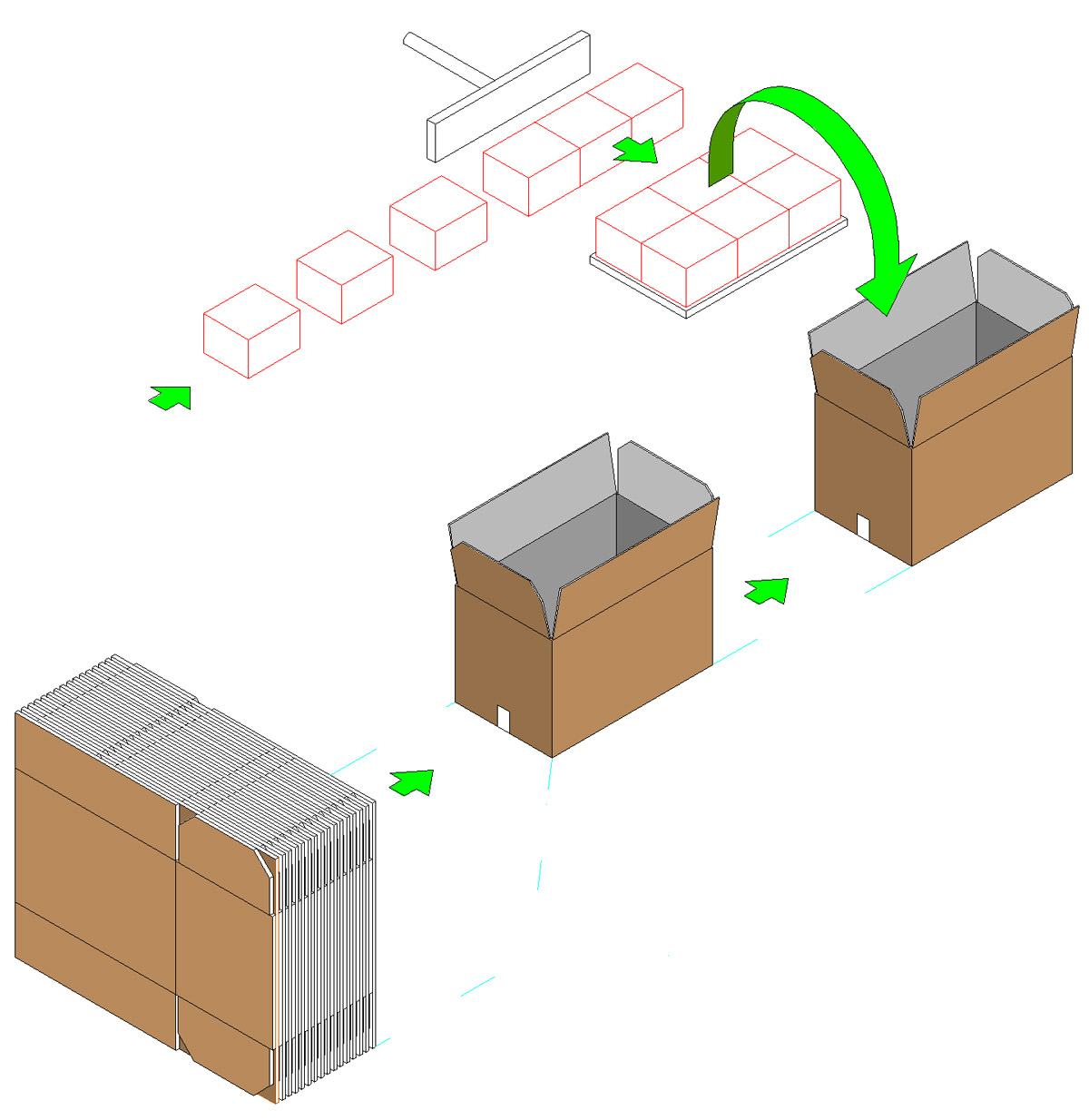

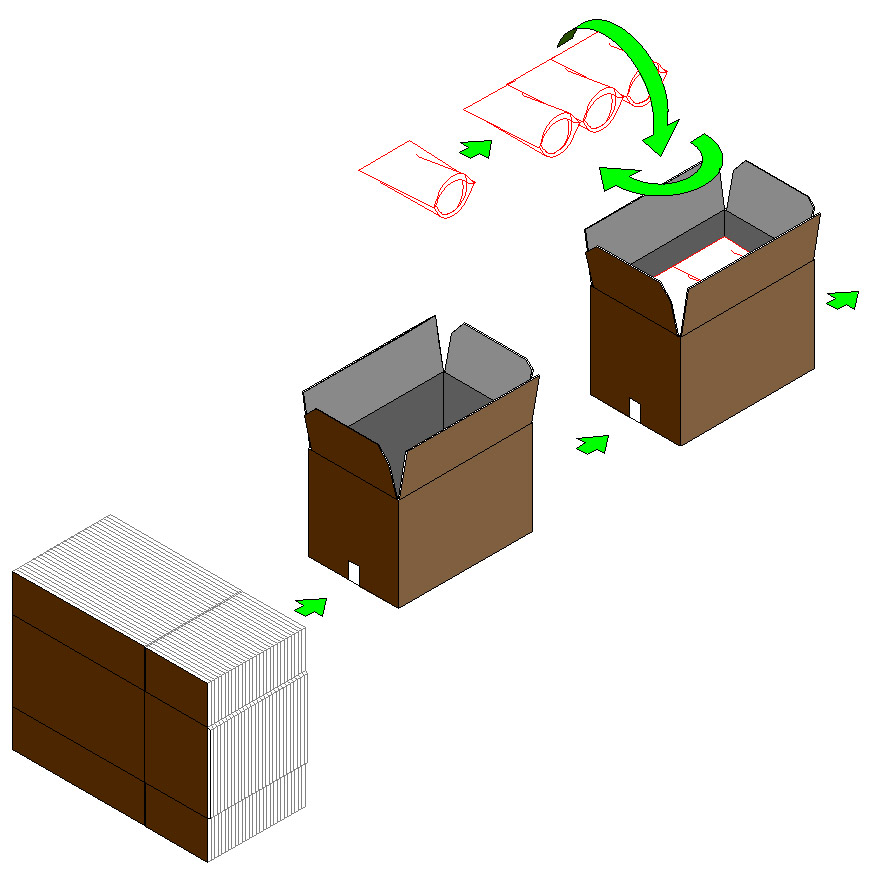

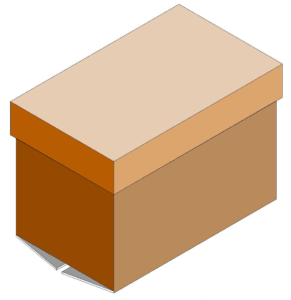

Process Flow