Enables to work with the same efficiency and speed than a single head

The position of the cases when casepacking is always the same, but the product collation can be both longitudinal and transversal, that is why the packages have to be turned in the collation table and this is possible thanks to this new head.

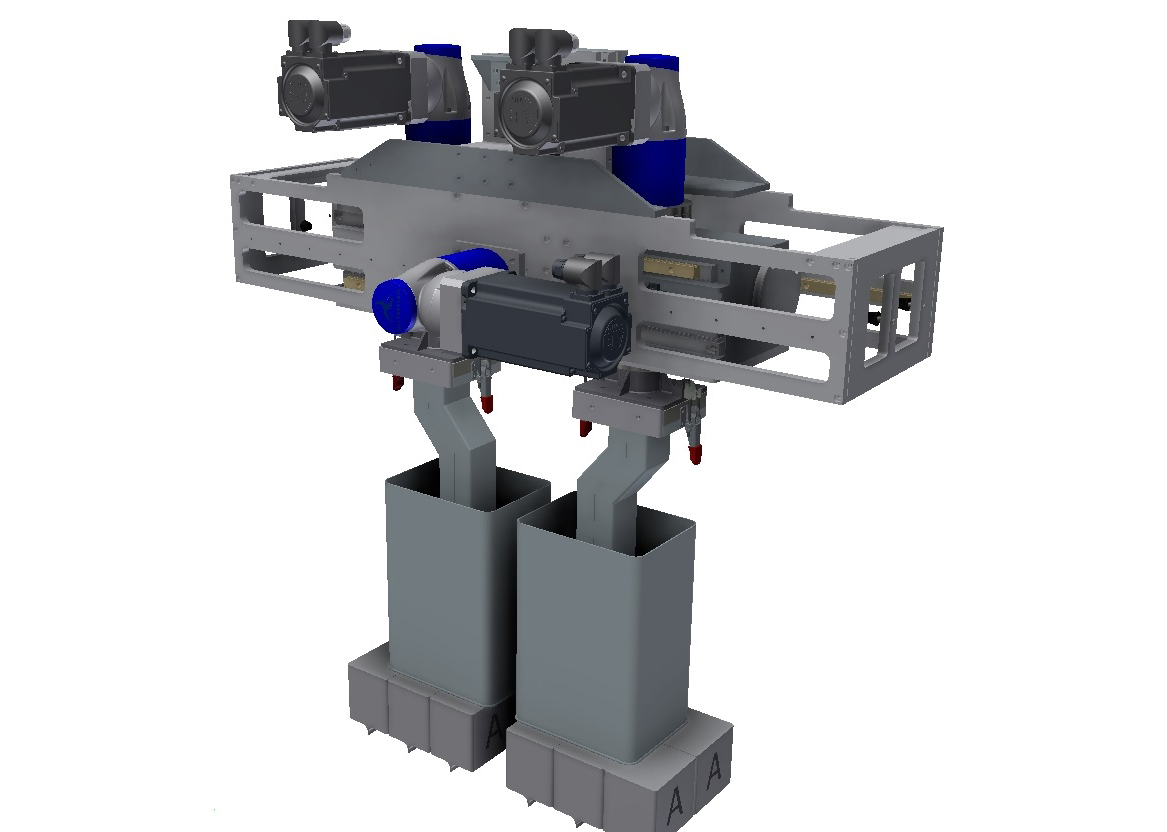

When the head is double (multiple simultaneous filling of cases) and with turning device, this should be necessarily equipped with the separator, to avoid the vertexes of the collation to collide with each other.

The turning movement is performed through a one single servomotor placed in the central axis of the suction cup, enabling the collation turn from 0 to 360º. At the same time, the distance from the head is controlled by a servomotor with suction cups.

Constructed in aluminium, enables to work with the same efficiency and speed than a single head, achieving thus a significant reduction of weight.

The main advantages of this new head are coming from the high flexibility when casepacking any type of collation, irrespective of its layout, before a one single case position. Savings in cost and maintenance are more than significant as the servomotor transmission to the opening and turning device is direct, avoiding the use of external elements such as pulleys, belts or chains.

This new design, together with its easy adaptability to new formats and final display provide a great versatility for future applications.