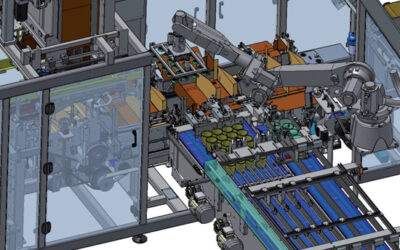

PRODEC presents its complete end-of-line with robotic case packing and palletizing. Modular, compact and flexible solution for side case packing in wrap cartons, designed for medium capacities. The Wrap 100 case packer has 3 stations and incorporates servomotors to ensure that movements are optimized to maximize speed. Suitable for production rates of up to 22 cartons/minute, this model stands out for its ease of format changeover, accessibility to all its mechanisms and easy maintenance....

News

PRODEC participates in hispack 2018

Prodec will participate in the next edition of HISPACK, which will take place in Barcelona from May 8 to 11. Our sales team will be pleased to assist you and show you our latest news. You can request your free one-day ticket by sending an e-mail to sales@prodec.es. We hope to see you there soon!

Thank you for visiting us at Interpack 2017!

On behalf of the entire PRODEC team, thank you for visiting us at Interpack 2017! It has been a pleasure to meet with you to present our latest innovations. Our entire sales team is at your disposal to give you more details about our developments in end-of-line equipment. Do not hesitate to contact us if you have any questions. See you at Interpack 2020!

Prodec participates in Interpack 2017

Prodec will participate in the next edition of Interpack that will take place in Düsseldorf, Germany, from May 4 to 10, in hall 13 stand C35.

We are pleased to invite you to visit our booth and present our latest innovations for your end-of-line needs.

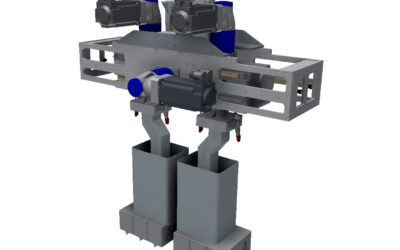

PRODEC at the cutting edge of innovation: new turning separator head

Prodec has designed a new turning separator head, which introduces the different type of packages into the case without changing the position of the same, irrespectively of the product position arriving from the infeed conveyor.

New R&D department

Since PRODEC is continuously working toward greater customer satisfaction, a new R&D department has been created in pursuit of operational efficiency, both in design as well as in production.

Discover our latest innovations in PROPAK ASIA 2016

PRODEC’s range offers a great variety of secondary packaging equipment, such as Top, Side and Bottom loading casepacker, Robotic loadingcasepacker in RSC and wraparound systems. In turn, we have Gantry and Robotic palletizers, Top and Side loading cartoners, as well as complete end of line solutions and Turn key projects.

New DELTA with tilting head generation

Prodec has designed its first DELTA with Tilting head casepacking equipment to place all kind of flexible packaging into the case, either in upright or flat position. We provide cutting edge technology and innovation in a same equipment with two different casepacking available depending on our customers needs.

New application with robot for the casepacking of small cups

PRODEC, at the cutting edge of innovation and development (given the high demand from customers producing this type of packaging) has designed and developed a new casepacking application for this new packaging in wrap case.

It is an automatic casepacker Mod. RBMW-140. It is currently common to find in supermarkets and superstores new packages containing easy-to-prepare and convenience food. They are individual small plastic cups easy to carry and to be consumed at any time with only 5 minutes preparation.

New application for the side casepacking of flexible packaging

PRODEC, at the cutting edge of innovation and development, has designed a new application for the side casepacking of flexible packaging. The main advantage of this new equipment is the upright position of the package into the case. It is a side casepacker Mod. PRSF-310, grouping by means of stacker and pick & place. The product infeed is done by buckets or stacker that makes the collation of the packages, the Pick & Place takes the packages and place them in another bucket area, thus...

PRODEC presents its new WEBSITE

We have redesigned our web to offer an updated, practical, useful and above all, the most suitable site to provide the best service to our users and customers. We have sought to improve the customer experience through the improvement of the end-of-line customized solutions which allows faster information access to the equipment.

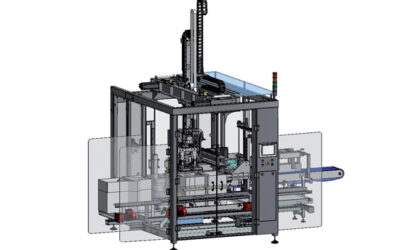

New head by grippers for rigid packages

PRODEC has completed a project for one of the most important multinational companies leader in the food market. PRODEC has designed the first top case packer for jars. It is a top case packer type DELTA, model D-104, designed for the casepacking of rigid or semi-rigid stackable containers. The casepacking of jars is made by a head of grippers, including a format change-over to adaptable suction cups to multiple formats.

New applications for flexible packages

RODEC has developed a new side case packing application for flexible packages, where the machine is capable to case packed the product either flat and in upright position. We have two different modalities for this new case packing system:

Prodec introduces hygienic design

After several studies and receiving quite a few food multinational requests, PRODEC has developed the so-called “hygienic design” for some of their equipment. The design of an equipment or facilities is considered “hygienic” as long as establishes, as a preventive measure, the specifications to reduce or eliminate the risk of a source of pollution, both directly and indirectly.