Introduction: Benefits of Automation in the Case Packing Industry

Prodec Equipos de Envasado, a part of the Xolertic Group, has been a prominent name in the automation of secondary packaging solutions for over 50 years. Specializing in automated case packing and cartoning of flexible packaging, including doypacks, pouches, flat-bottom bags, and pillow bags, their expertise has revolutionized the secondary packaging sector. In this article, we will explore the exciting world of flexible packaging case packing automation and how it optimizes production efficiency.

Advantages of Automation in Flexible Packaging Case Packing

- Enhancing Efficiency, Quality, and Profitability

The implementation of automation in flexible packaging case packing processes offers a myriad of advantages. One of the primary benefits is the substantial enhancement in production efficiency. Automated systems perform tasks with precision and speed, reducing the likelihood of errors and ensuring consistently high-quality packaging. This efficiency not only results in cost savings but also accelerates the production cycle, thereby increasing profitability. - Cost Savings through Automation

Automation in case packing leads to significant cost savings, which is vital for businesses operating in today’s competitive market. The reduction in labor costs, minimized material wastage, and streamlined operations translate into a substantial improvement in the bottom line. In particular, the use of robots in case packing offers the advantage of round-the-clock productivity without the need for rest or breaks, further contributing to cost-effectiveness. - Consistency and Quality Assurance

Automation guarantees a consistent and standardized packaging process. This eliminates the variability introduced by human labor and ensures that every package meets the defined quality standards. In industries such as food and pharmaceuticals, where product integrity is paramount, automation is the key to maintaining stringent quality assurance requirements.

Automation in Countries with Lower Labor Costs

In a global context, the automation of flexible packaging case packing becomes even more appealing in countries with lower labor costs, such as India. While labor cost savings are a notable advantage, it is essential to consider the long-term benefits. Automation offers consistent quality and productivity, reducing the risk of human errors and the associated costs, making it a wise investment for businesses in countries with varying labor costs.

The Role of Pick and Place Case Packing Systems

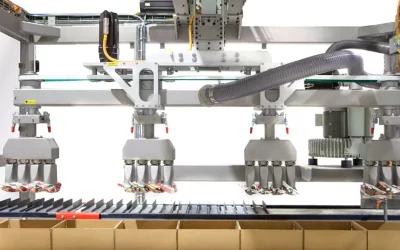

Prodec’s expertise lies in handling flexible case packing, particularly in dealing with notoriously unstable packaging formats. They employ advanced systems, including pick and place case packing, such as the Cartesian case packing. This robotic solution excels in precisely picking up and placing items into cases, ensuring a secure and organized packaging process.

Prodec also specializes in spider robot case packing and other robotic solutions. These robotic systems offer high flexibility, adaptability, and precision in case packing, making them ideal for a wide range of products and packaging formats. The spider robot’s multi-axis design enables intricate case packing in a controlled and efficient manner.

Sensory Integration in Case Packing

Automation in flexible packaging case packing is incomplete without the incorporation of sensory technologies. Prodec employs advanced sensory solutions, including vision systems, safety light curtains, and other sensors. These technologies play a crucial role in ensuring precise case packing, detecting anomalies, and maintaining safety during the packaging process.

Optimizing Efficiency and Quality through Automation

The automation of flexible packaging case packing has become a cornerstone of the industry’s success. Prodec Equipos de Envasado, with its rich history of over 50 years, stands as a leader in revolutionizing the secondary packaging sector. Their ability to automate flexible case packing while stabilizing the often unpredictable packaging formats has earned them a well-deserved reputation. Automation not only enhances production efficiency but also ensures consistent quality, cost savings, and long-term sustainability in an increasingly competitive global market.